Steelcase Panel System Assembly Instructions: A Comprehensive Guide

Steelcase Panel System Assembly – A Comprehensive Guide. This resource details installation, covering configurations, corners, curves, troubleshooting, safety, and support links.

A step-by-step guide for panel assembly is essential for successful installation, providing a clear outline of the process with diagrams and component explanations.

Remember, all electrical installations require a qualified electrician, adhering to local codes and regulations for safe and compliant Steelcase power panel systems.

The Walls Installation Hotline offers support for Steelcase Walls products, connecting you with experts and processes for a smooth installation experience.

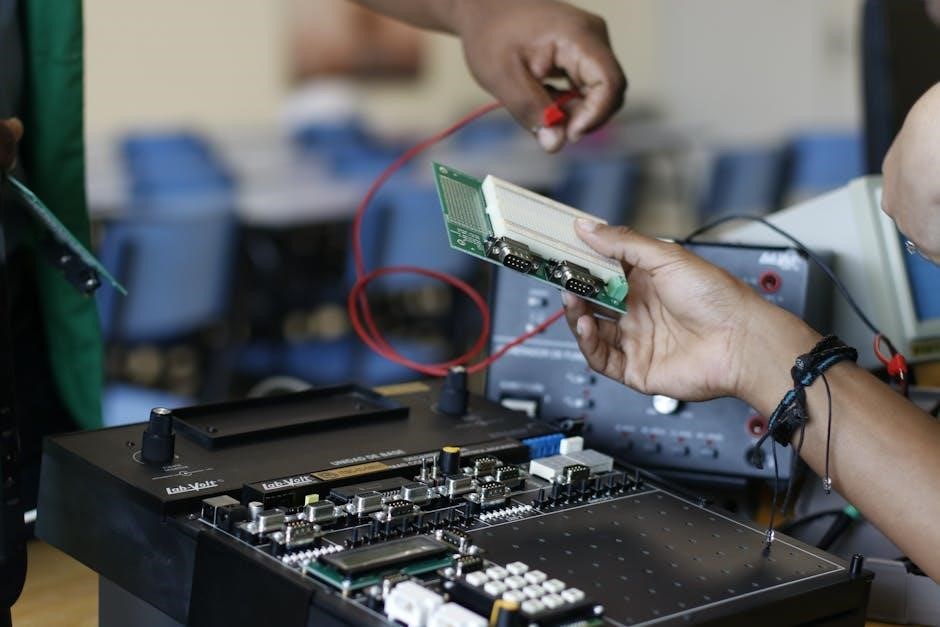

Cubicle installation demonstrations are available to assist with the setup process, ensuring proper assembly and functionality of your Steelcase panel system.

Steelcase panel systems offer adaptable workspace solutions, prioritizing modularity and user-centric design. This comprehensive guide streamlines the installation process, ensuring a successful setup. Understanding these systems involves recognizing their core components and configurations. Proper assembly, detailed here, maximizes functionality and aesthetic appeal.

From basic layouts to complex curves, this guide supports various Steelcase configurations. Remember, electrical work necessitates a qualified electrician for code compliance and safety.

Understanding System Components

Steelcase panel systems comprise diverse elements: panels themselves, corner and post components for structural integrity, and trim/edge details for a finished look. Sight-sound barriers enhance privacy, while latch end covers secure doorway panels. Familiarity with these parts—and how they interlock—is crucial for efficient assembly.

Correct component identification, referencing assembly diagrams, prevents errors during installation.

Panel Types and Sizes

Steelcase offers a variety of panel types, including standard, doorway, and power panels, each designed for specific functions within a workspace. Panel sizes vary significantly, impacting layout flexibility. Accurate measurement and selection are vital before assembly.

Understanding available dimensions ensures optimal space utilization and a seamless installation process.

Post and Corner Components

Steelcase panel systems utilize posts and corner components to create stable and interconnected workstations. Corner posts require precise alignment during installation, ensuring structural integrity. End covers secure to these posts, concealing hardware and providing a finished look.

Proper attachment of these components is crucial for a robust and aesthetically pleasing cubicle setup.

Trim and Edge Details

Steelcase panel systems feature top trim that secures with socket head screws, disengaging from inner tabs for removal. Edge details, including end covers, contribute to a polished appearance and conceal internal components. Careful attention to trim alignment is vital for a professional finish;

Properly installed trim enhances both aesthetics and durability.

Tools Required for Assembly

Successful Steelcase panel assembly necessitates specific tools. Essential hand tools include screwdrivers and potentially wrenches for hardware tightening. Power tools, while optional, can expedite the process. Prioritize safety by utilizing appropriate personal protective equipment – gloves and eye protection are crucial.

Ensure all tools are in good working order before commencing installation.

Essential Hand Tools

For Steelcase panel system assembly, a set of screwdrivers – both Phillips and flathead – is paramount. A socket wrench set, particularly with socket head screws, is also vital for securing components. Rubber mallets can aid gentle adjustments, preventing damage. Measuring tapes ensure accurate alignment during installation.

These tools form the foundation of a successful build.

Power Tools (Optional)

While hand tools are sufficient, a power screwdriver with adjustable clutch settings can expedite Steelcase panel assembly, reducing fatigue. A drill, used cautiously with appropriate bits, assists with pilot holes if needed. However, avoid over-tightening! Power tools should supplement, not replace, careful manual work.

Use with caution to prevent damage during installation.

Safety Equipment

Prioritize safety during Steelcase panel system assembly! Wear safety glasses to protect against debris. Work gloves provide grip and prevent cuts. Steel-toe boots are recommended when handling heavier components. When dealing with electrical connections (power panels), adhere strictly to electrical safety guidelines and utilize appropriate insulated tools.

Personal protective equipment is crucial for a safe installation.

Pre-Assembly Preparation

Successful Steelcase panel system installation begins with thorough preparation. First, conduct a complete inventory of all parts against the packing list. Next, prepare your workspace – ensure ample clear space for assembly and movement. Finally, carefully review the assembly diagrams and manuals to familiarize yourself with the process and components.

Proper planning prevents errors!

Inventory of Parts

Before commencing Steelcase panel assembly, meticulously verify all components against the provided packing list. Confirm the quantity of panels, end covers, corner posts, trim pieces, and all hardware – screws, bolts, and connectors. Note any discrepancies immediately and contact customer support for replacements. A complete inventory minimizes delays during installation.

Workspace Preparation

Designate a spacious, clean, and well-lit area for Steelcase panel assembly. Protect the flooring with drop cloths to prevent scratches. Ensure ample room for maneuvering panels and accessing components. Clear the space of obstructions and organize tools for efficient workflow. Proper preparation streamlines installation and minimizes potential damage;

Reviewing Assembly Diagrams

Before commencing Steelcase panel installation, thoroughly examine the provided assembly diagrams and manuals. Familiarize yourself with component orientation, hardware placement, and sequential steps. Understanding the visual guides prevents errors and ensures correct assembly. Diagrams illustrate critical details, like end cover removal and latch panel procedures, for a smooth process.

Step-by-Step Panel Assembly

Begin by attaching end covers and corner posts, ensuring secure alignment. Next, install sight-sound barriers, positioning them opposite the intended door swing. Carefully lift top trim straight up, disengaging inner tabs before removal. Back off socket head screws for cover detachment. Verify proper component fit throughout each assembly stage.

Attaching End Covers and Corner Posts

To begin, remove existing end covers by lifting upwards, disengaging the inner upright tabs after loosening socket head screws. Install new latch end covers on panels flanking doorways. Ensure corner posts are firmly seated before attaching end covers, creating a stable connection. Proper alignment is crucial for a professional finish.

Installing Sight-Sound Barriers

Install sight-sound barriers on the edge of end covers and corner posts, positioning them opposite the door swing for optimal privacy. These barriers easily attach, enhancing acoustic performance and visual separation within the workspace. Ensure a secure fit to maximize sound dampening and maintain the panel system’s integrity.

Securing Top Trim and Hardware

Begin by lifting the top trim straight up, then back off the socket head screw until the assembly moves approximately 1/2 inch, disengaging the cover from inner tabs. Lift the end cover away from the panel. Secure all hardware tightly, ensuring panels are stable and aligned. Proper trim installation completes a professional finish;

Electrical Connections (Power Panels)

Important: All electrical installations for Steelcase power panels must be performed by a qualified electrician, strictly adhering to all applicable local codes and regulations. The power panel supply system requires careful installation to ensure safety and functionality. Verify proper grounding and connections before operation, following the system’s documentation.

Qualified Electrician Requirement

Crucially, all electrical work related to Steelcase power panels demands a licensed and qualified electrician. This ensures compliance with local and national electrical codes, safeguarding against hazards. Improper installation can lead to fire risks or system malfunctions. Verification of credentials is paramount before commencing any electrical connections.

Power Panel Supply System Installation

Installation of the Steelcase Power Panel Supply System requires meticulous attention to detail by a qualified electrician. This involves connecting the power supply to the panels, ensuring proper grounding, and verifying voltage compatibility. Adherence to the manufacturer’s instructions and local electrical codes is absolutely essential for safe operation.

Adherence to Electrical Codes

Steelcase emphasizes that all electrical installations, particularly those involving Power Panel systems, must comply with all applicable local and national electrical codes and regulations. A qualified electrician is legally required to perform these connections, ensuring safety and preventing potential hazards. Ignoring these codes voids warranties and poses risks.

Doorway Panel Installation

To install doorway panels, begin by removing existing end covers – lift straight up and disengage from inner tabs by backing off socket head screws. Then, install new latch end covers on panels flanking the doorway. Ensure proper alignment by adjusting the panel after cover removal, preparing for a seamless transition.

Removing Existing End Covers

Begin the process by lifting the end cover straight up, carefully disengaging it from the inner upright tabs. Simultaneously, back off the socket head screw approximately 1/2 inch; this action allows the cover to move freely. Once disengaged, lift the end cover completely away from the panel, preparing for replacement.

Installing Latch End Covers

After removing the existing end covers from panels flanking the doorway, prepare to install the new latch end covers. Ensure proper orientation – the latch-side cover should align with the doorway’s swing. Carefully position the cover and gently press it onto the panel, ensuring a secure and flush fit before proceeding.

Adjusting Panel Alignment

Precise panel alignment is crucial for a professional finish. After installing latch end covers, back off the socket head screw approximately 1/2 inch. This disengages the cover from inner tabs, allowing for minor adjustments. Gently shift the panel until perfectly aligned, then retighten the screw to secure its position.

Complex Configurations: Corners and Curves

Assembling corner panels requires careful attention to structural integrity. Ensure proper connection of corner posts and end covers for stability. Creating curved arrangements demands flexible components and precise alignment. Verify all connections are secure, maintaining the intended design. Prioritize a robust framework to support the overall panel system’s longevity.

Assembling Corner Panels

Corner panel assembly necessitates precise alignment of posts and panels, ensuring a seamless connection. Begin by attaching end covers and corner posts, verifying a flush fit. Double-check structural integrity at each joint, as corners bear significant stress. Secure all hardware tightly, maintaining stability and preventing future shifting.

Creating Curved Panel Arrangements

Achieving smooth curves requires flexible panel systems and specialized connectors. Carefully plan the radius and panel placement before assembly. Ensure consistent spacing between panels for a uniform aesthetic. Prioritize structural integrity; curved arrangements demand robust connections. Regularly inspect for alignment and stability throughout the installation process.

Ensuring Structural Integrity

Maintaining stability is paramount during and after assembly. Verify all hardware is securely tightened, focusing on corner posts and connections. Regularly inspect panels for any signs of shifting or looseness; Proper weight distribution is crucial, especially with add-ons. A solid foundation guarantees a safe and durable workspace configuration.

Troubleshooting Common Issues

Panel alignment problems often stem from uneven flooring or improperly installed end covers; re-check leveling and cover engagement. Hardware installation difficulties may require adjusted socket head screw backing. Electrical connection issues necessitate a qualified electrician’s review, ensuring code compliance. Consult diagrams for correct part placement.

Panel Alignment Problems

Misalignment frequently arises from uneven floor surfaces; utilize shims to level panels. Verify proper engagement of end covers and corner posts – lift and re-seat if necessary. Back off socket head screws slightly to allow for adjustment. Double-check assembly diagrams for correct orientation and component placement during re-alignment.

Hardware Installation Difficulties

If screws are difficult to tighten, ensure correct alignment of components. Avoid over-tightening, which can strip threads or damage panels. Verify you’re using the correct hardware specified in the assembly diagrams. If issues persist, slightly loosen adjacent hardware to relieve pressure, then re-attempt installation carefully.

Electrical Connection Issues

Electrical installations must be performed by a qualified electrician, adhering to all applicable codes. If connections are problematic, double-check wiring polarity and ensure secure connections within the power panel supply system. Immediately discontinue work and consult an electrician if you encounter sparking or unusual smells.

Safety Precautions During Assembly

Prioritize personal safety! Always wear appropriate personal protective equipment, including safety glasses and gloves. Utilize proper lifting and handling techniques to prevent injuries when moving Steelcase panels. Strict adherence to electrical safety guidelines is crucial during power panel connections; always disconnect power before working on electrical components.

Personal Protective Equipment

Essential safety gear is paramount during Steelcase panel assembly. Always wear safety glasses to protect your eyes from debris. Durable work gloves safeguard hands from sharp edges and potential cuts. Consider a back support belt when lifting heavier panel components to minimize strain and prevent injury.

Lifting and Handling Techniques

Proper lifting is crucial to avoid injury during Steelcase panel assembly. Bend at the knees, not the waist, keeping your back straight. Maintain a firm grip and hold panels close to your body. Utilize team lifting for heavier components, coordinating movements for safe and efficient handling.

Electrical Safety Guidelines

Always engage a qualified electrician for all power panel connections, strictly adhering to local electrical codes and regulations. Before any electrical work, disconnect power at the source. Never attempt repairs yourself; inspect wiring for damage before connecting. Ensure proper grounding and utilize appropriate safety equipment during installation.

Post-Assembly Inspection

Following assembly, meticulously check panel stability, ensuring a secure and level configuration. Verify all hardware—screws, bolts, and connectors—are firmly tightened to prevent future shifting. Critically, test the electrical system (if applicable) for proper functionality and safety, confirming adherence to code.

Checking Panel Stability

Post-installation, assess each panel’s stability by applying gentle pressure to various points. Ensure no excessive wobble or movement exists, indicating loose connections; Confirm the entire system feels structurally sound and capable of withstanding normal use. Address any instability immediately by re-tightening hardware or adjusting alignment.

Verifying Hardware Tightness

A thorough post-assembly inspection must include verifying the tightness of all hardware components. Systematically check every screw, bolt, and connector, ensuring they are securely fastened but not over-tightened. Loose hardware compromises stability and safety; retighten as needed. This step is crucial for long-term durability.

Electrical System Testing

Post-assembly, a qualified electrician must test all electrical connections within the power panel system. Verify proper grounding and voltage levels, ensuring adherence to all applicable electrical codes and regulations. Confirm functionality of outlets and power distribution. Document testing results for future reference and safety compliance.

Walls Installation Hotline & Support

The Walls Installation Hotline provides dedicated support for professionals installing Steelcase Walls products. Access expert guidance, troubleshooting assistance, and connections to vital resources. This hotline streamlines the installation process, ensuring a smooth experience and proper system functionality. Contact them for support during and after installation.

Resources and Documentation

For comprehensive assistance, visit the official Steelcase website for detailed assembly diagrams and manuals. These resources offer step-by-step guidance for various panel system configurations. Should you require further clarification, don’t hesitate to contact Steelcase customer support directly. They provide expert assistance and address specific installation queries.

Steelcase Official Website

The Steelcase official website is the primary hub for all product information and support. Here, you’ll find downloadable assembly diagrams, detailed manuals for various panel systems, and frequently asked questions. Explore the site to access specifications, warranty details, and connect with customer support for personalized assistance with your installation.

Assembly Diagrams and Manuals

Detailed assembly diagrams and comprehensive manuals are crucial for a successful Steelcase panel system installation. These resources visually guide you through each step, clarifying component placement and hardware usage. Downloadable versions are often available on the Steelcase website, ensuring you have readily accessible instructions throughout the entire process.

Contacting Customer Support

For personalized assistance with your Steelcase panel system assembly, reach out to their dedicated customer support team. You can find contact information – including phone numbers like 1-888-783-3522 – and online support portals on the official Steelcase website. They provide expert guidance and address specific installation challenges.

Cubicle Installation Demonstration Resources

Enhance your Steelcase panel system installation with readily available demonstration resources. These visual guides, as noted from February 26, 2013, offer step-by-step walkthroughs of the assembly process. Access these resources online to clarify complex configurations, proper hardware usage, and ensure a smooth, efficient cubicle setup.

Maintenance and Care of Steelcase Panels

Maintaining your Steelcase panel system ensures longevity and a professional appearance. Regularly inspect panels for stability and hardware tightness post-assembly. Gentle cleaning with appropriate solutions preserves surface quality. Address any alignment issues promptly to prevent further complications. Proper care extends the life of your investment.